The phrase “Made in China” has undergone a remarkable transformation over the past decades. Once associated with budget alternatives, it now represents precision, innovation, and exceptional value in manufacturing—particularly in the jewelry industry. Today’s Chinese manufacturers combine centuries-old craftsmanship traditions with cutting-edge technology to deliver products that meet the highest international standards while remaining competitively priced.

A Legacy Built on Centuries of Craftsmanship

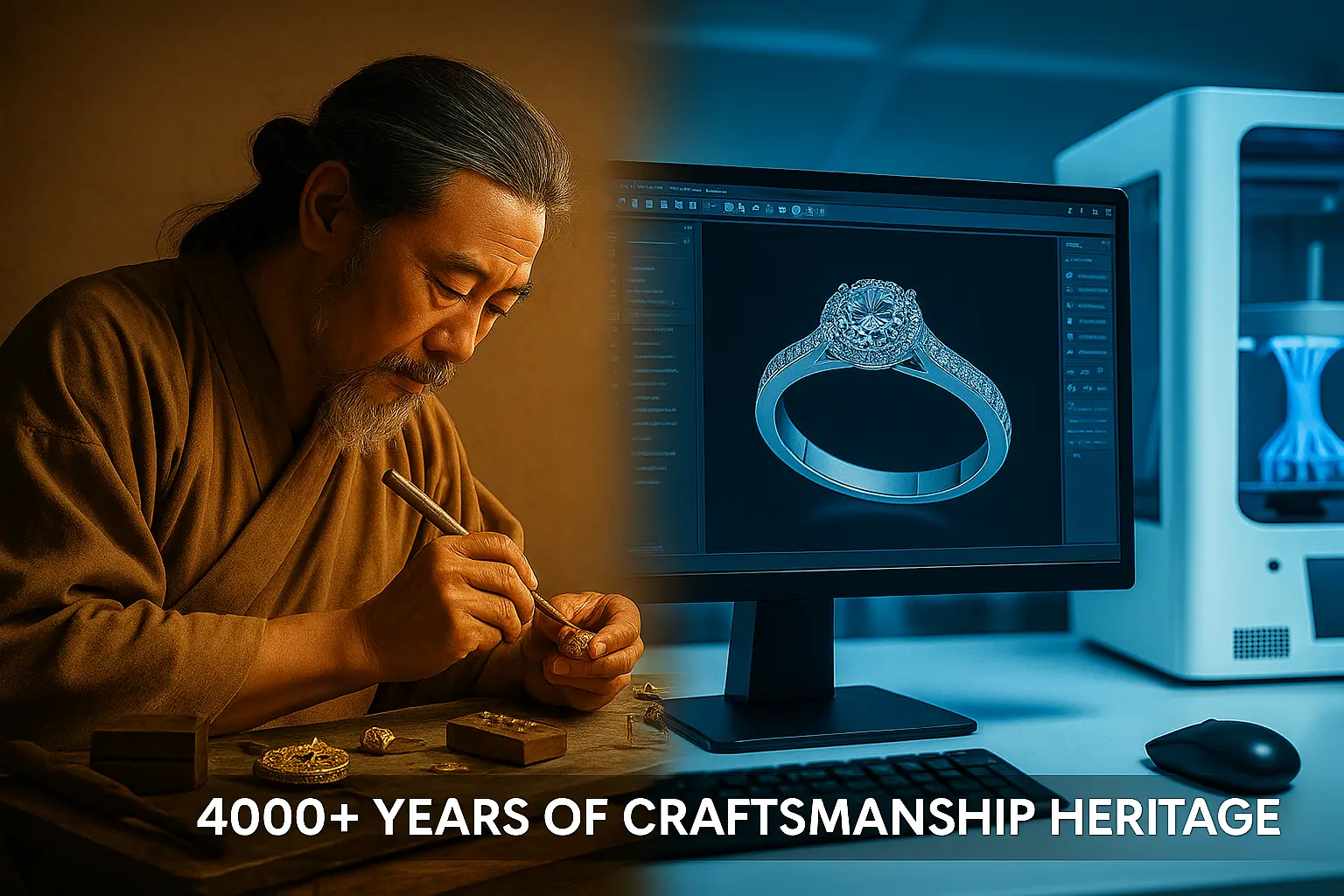

China’s jewelry manufacturing excellence isn’t accidental—it’s rooted in over 4,000 years of metalworking and gem-cutting traditions. Ancient Chinese artisans developed sophisticated techniques for working with precious metals and stones, many of which form the foundation of modern jewelry production methods.

This historical expertise has been carefully preserved and passed down through generations of craftsmen. Traditional hand-engraving techniques, intricate filigree work, and precise stone-setting methods continue to influence contemporary production processes. The result is a manufacturing culture that values attention to detail and takes pride in creating beautiful, durable pieces.

What sets Chinese manufacturing apart is how seamlessly these ancient techniques integrate with modern technology. Master craftsmen work alongside precision machinery, ensuring that each piece benefits from both human artistry and technological accuracy.

Technical Excellence Driving Innovation

Modern Chinese jewelry factories operate with state-of-the-art equipment that rivals any facility worldwide. Computer-aided design (CAD) systems enable precise modeling before production begins, while 3D printing technology allows for rapid prototyping and testing of new designs.

The precision achieved through advanced manufacturing processes is remarkable. CNC machines can cut settings with tolerances measured in hundredths of millimeters, ensuring perfect fits for gemstones of any size. Laser welding technology creates joints that are virtually invisible while maintaining superior strength.

Quality control systems in leading Chinese facilities employ multiple checkpoints throughout the production process. Each piece undergoes thorough inspection at various stages, from initial casting to final polishing. This systematic approach significantly reduces defects and ensures consistent quality across large production runs.

Many Chinese manufacturers have earned internationally recognized certifications, including ISO 9001 for quality management and various precious metal purity certifications. These credentials demonstrate their commitment to meeting global standards and provide customers with confidence in their purchases.

The Skilled Workforce Advantage

Behind every exceptional piece of jewelry is a skilled craftsperson, and China’s jewelry industry benefits from one of the world’s most talented workforces. Specialized training programs, often spanning several years, prepare artisans for the demanding precision required in jewelry manufacturing.

The apprenticeship system remains strong in China, with experienced masters teaching younger craftspeople the subtle skills that can’t be learned from textbooks. This knowledge transfer ensures that traditional techniques don’t disappear while continuously improving efficiency and quality.

Chinese jewelry workers develop expertise in multiple areas—from initial design work to final quality inspection. This versatility allows for better communication between production stages and helps identify potential issues before they become problems. The result is smoother production flows and higher-quality finished products.

The dedication to craftsmanship is evident in the details. Hand-finishing work on pieces requiring personal attention receives the same careful treatment whether the order is for ten pieces or ten thousand. This consistency in approach helps explain why many luxury brands choose Chinese manufacturers for their production needs.

Cost-Effectiveness Without Quality Compromise

One of the most compelling advantages of Chinese jewelry manufacturing is the ability to deliver exceptional value without sacrificing quality. This cost-effectiveness stems from several key factors that benefit customers directly.

Economies of scale play a significant role. Large production facilities can spread fixed costs across many units, reducing per-piece expenses while maintaining high standards. Efficient supply chain management ensures that raw materials are sourced cost-effectively without compromising on grade or authenticity.

The competitive manufacturing environment in China drives continuous improvement in processes and efficiency. Manufacturers constantly seek ways to reduce waste, improve productivity, and streamline operations—savings that are typically passed on to customers.

However, cost-effectiveness doesn’t mean cutting corners. Leading Chinese manufacturers understand that their reputation depends on consistent quality, so they invest heavily in training, equipment, and quality control systems. The goal is to provide better value, not cheaper alternatives.

This approach has proven successful for businesses like Minye Jewelry, which has built strong relationships with international clients by delivering high-quality pieces at competitive prices. Their success demonstrates how Chinese manufacturing can meet diverse customer needs while maintaining excellent standards.

Customization and Production Flexibility

Chinese jewelry manufacturers excel at adapting to customer requirements, whether for unique custom pieces or modifications to existing designs. This flexibility stems from both technical capabilities and a service-oriented approach to business relationships.

Rapid prototyping capabilities allow customers to see and evaluate designs before committing to full production runs. 3D printing and sampling services help refine details and ensure that the final product matches expectations exactly. This collaborative approach reduces the risk of misunderstandings and helps create better final products.

Production flexibility extends to order sizes as well. Whether a customer needs a single custom piece or thousands of identical items, Chinese manufacturers can typically accommodate the request efficiently. This scalability makes them valuable partners for businesses of all sizes.

The ability to work with various materials and techniques under one roof is another significant advantage. A single facility might offer casting, stone setting, engraving, and finishing services, simplifying the production process and improving quality control.

Quality Assurance and International Standards

Quality assurance in Chinese jewelry manufacturing has reached impressive levels of sophistication. Leading facilities employ multi-stage inspection processes that examine everything from raw material purity to final product durability.

Testing procedures often exceed basic requirements, with manufacturers using advanced equipment to verify metal composition, stone authenticity, and structural integrity. These comprehensive evaluations help ensure that products will perform well in real-world conditions and maintain their appearance over time.

Many Chinese manufacturers maintain certifications from international quality organizations and undergo regular audits to verify their processes. This commitment to transparency builds trust with overseas customers and demonstrates dedication to maintaining high standards.

Customer satisfaction tracking provides valuable feedback for continuous improvement. Manufacturers actively seek input from clients and use this information to refine their processes and address any concerns promptly.

The Future of Chinese Jewelry Manufacturing

Looking ahead, Chinese jewelry manufacturing continues to evolve and improve. Investments in new technology, environmental sustainability, and worker training suggest that the quality and value advantages will only strengthen over time.

Emerging technologies like artificial intelligence and advanced robotics are being integrated thoughtfully, enhancing precision while preserving the human elements that make jewelry special. This balanced approach ensures that technological advancement serves to improve rather than replace traditional craftsmanship.

Environmental considerations are becoming increasingly important, with manufacturers adopting cleaner processes and more sustainable practices. These improvements benefit everyone by reducing environmental impact while often improving efficiency and reducing costs.

Conclusion

China’s jewelry manufacturing industry represents a unique combination of traditional craftsmanship, modern technology, skilled workers, and efficient business practices. This combination delivers exceptional value for customers seeking high-quality jewelry at competitive prices.

The transformation of “Made in China” from a budget indicator to a quality assurance reflects real improvements in capabilities and standards. For businesses and consumers seeking reliable jewelry manufacturing partners, China offers compelling advantages that are difficult to match elsewhere.

Companies like Minye Jewelry exemplify this new standard, building lasting relationships with international clients through consistent quality and reliable service. As the industry continues to evolve, these advantages are likely to become even more pronounced.

Whether you’re looking for custom pieces, large production runs, or unique designs, Chinese jewelry manufacturers have demonstrated their ability to deliver results that meet the highest standards while providing excellent value for investment.