The jewelry industry has witnessed remarkable technological advances in recent years, particularly in casting techniques that enable the creation of superior silver moissanite pieces. Whether you’re a jewelry enthusiast, a professional buyer, or simply curious about what makes quality jewelry exceptional, understanding these manufacturing processes helps you appreciate the craftsmanship behind each piece.

Modern casting methods have transformed how manufacturers produce silver moissanite jewelry, combining traditional artistry with cutting-edge technology. This comprehensive guide explores the advanced techniques that separate ordinary pieces from truly exceptional ones.

The Foundation: Understanding Modern Casting Methods

Casting remains the cornerstone of jewelry manufacturing, and the techniques employed directly impact the final product’s quality, durability, and aesthetic appeal.

Lost-Wax Casting: The Time-Tested Standard

Lost-wax casting continues to be the preferred method for creating intricate silver moissanite jewelry. This process begins with a detailed wax model that captures every design element. The wax model gets encased in a heat-resistant investment material, which forms a mold when heated. As the investment hardens, the wax melts away, leaving a precise cavity for molten silver.

This technique offers unparalleled design flexibility, allowing for complex patterns and delicate details that other methods cannot achieve. The process ensures each piece maintains consistent quality while preserving artistic vision.

Vacuum-Assisted Casting: Enhanced Precision

Vacuum-assisted casting represents a significant advancement in jewelry manufacturing. This method removes air from the casting chamber before introducing molten metal, eliminating porosity and ensuring complete mold filling.

The vacuum environment produces several critical benefits. First, it prevents oxidation during the melting process, resulting in purer silver with better structural integrity. Second, it ensures molten silver reaches every intricate detail of the mold, capturing fine textures and sharp edges that define quality jewelry. Third, it significantly reduces internal defects that can compromise durability.

Centrifugal Casting: Force-Driven Excellence

Centrifugal casting uses rotational force to drive molten silver into mold cavities. The spinning motion creates pressure that pushes metal into the finest details while forcing air bubbles outward. This technique works particularly well for pieces with extended elements or complex geometries.

When compared to vacuum casting, centrifugal methods excel at producing certain design types, especially those with thin walls or elongated features. However, the choice between methods often depends on the specific design requirements and the manufacturer’s expertise.

At Minye Jewelry, we carefully evaluate each design to determine the optimal casting approach, ensuring every piece meets our exacting standards for quality and precision.

Precision Techniques for Moissanite Settings

Working with moissanite requires specialized knowledge, as this gemstone has unique properties that demand careful handling during the casting process.

Pre-Setting Considerations

Unlike some manufacturing approaches, advanced techniques often involve setting moissanite stones after casting completion. This prevents exposing the stones to extreme temperatures that could affect their optical properties. However, the casting process must account for precise setting locations, requiring exact dimensions and proper metal thickness around prong or bezel areas.

Manufacturers must calculate metal shrinkage rates accurately. Silver contracts as it cools, and failing to compensate for this shrinkage results in settings that don’t properly accommodate moissanite stones. Experienced craftspeople adjust mold dimensions to ensure final settings match specifications perfectly.

Temperature Control During Casting

Precise temperature management proves critical when creating settings for moissanite. Silver must reach optimal fluidity to fill intricate setting details without overheating, which can cause grain structure problems or excessive oxidation.

Modern casting equipment includes sophisticated temperature monitoring systems that maintain molten silver within a narrow ideal range, typically between 955°C and 980°C for sterling silver. This precision ensures consistent results across production runs while maintaining the metal’s optimal properties.

Preventing Thermal Shock

Although moissanite exhibits excellent thermal stability compared to many gemstones, proper protocols still matter. When stones are set after casting, the metal must cool completely and undergo proper annealing before stone setting begins. This prevents residual heat from affecting the moissanite or creating stress points in the metal that could compromise setting security.

Advanced Surface Finishing Methods

The casting process produces the basic form, but superior jewelry requires meticulous finishing to achieve its final beauty.

Strategic Post-Cast Polishing

Professional finishing begins with careful removal of sprues and investment material remnants. Craftspeople then progress through increasingly fine abrasive stages, each removing scratches from the previous step while creating a smoother surface.

This gradual refinement process cannot be rushed. Aggressive polishing might seem efficient but generates excessive heat that can warp delicate elements or create uneven surfaces. Patient, methodical work produces the flawless surfaces that characterize premium jewelry.

Achieving Mirror-Finish Excellence

The coveted mirror finish on silver requires both skill and proper technique. After initial polishing stages, craftspeople use specialized compounds and buffing wheels to create surfaces that reflect light with exceptional clarity.

Different areas of a piece often require different finishing approaches. Flat surfaces might receive high polish, while textured areas retain their designed finish. This selective finishing adds depth and visual interest to the final piece.

Rhodium Plating for Enhanced Performance

Many premium silver moissanite pieces receive rhodium plating, which provides multiple benefits. This thin layer of rhodium, a platinum-group metal, creates a bright white surface that resists tarnishing far better than silver alone. The plating also adds scratch resistance and enhances the overall appearance.

Proper plating requires scrupulously clean surfaces and controlled electrical current. The process deposits rhodium atoms uniformly across the surface, creating a durable protective layer that maintains its beauty through years of wear.

Minye Jewelry applies rhodium plating using industry-leading techniques that ensure even coverage and optimal adhesion, giving our silver moissanite pieces exceptional longevity and lasting brilliance.

Quality Control and Inspection Protocols

Advanced casting techniques mean little without rigorous quality verification at every production stage.

Porosity Detection Methods

Internal voids or porosity represent one of the most serious casting defects. These microscopic air pockets weaken the metal structure and can lead to eventual failure. Professional manufacturers employ multiple detection methods to identify and eliminate porous pieces.

Visual inspection under magnification reveals surface porosity, while X-ray examination can detect internal voids. Ultrasonic testing provides another verification layer, using sound waves to identify density variations within the metal structure.

Stone Security Verification

For moissanite jewelry, setting security demands particular attention. Each stone must sit securely in its setting with proper tension from prongs or bezels. Inspectors verify that settings hold stones firmly without excessive pressure that could cause damage.

Professional testing involves gentle pressure application from multiple angles to confirm stones remain secure. Settings must also allow adequate light entry to maximize moissanite’s exceptional brilliance and fire.

Industry Standard Certifications

Reputable manufacturers maintain certifications that verify their adherence to quality standards. These certifications provide assurance that pieces meet specific criteria for metal purity, construction quality, and manufacturing practices.

For silver jewelry, hallmarking indicates metal content, typically 925 for sterling silver. This mark represents a legally recognized guarantee of metal purity that protects consumers and upholds industry integrity.

Investment Casting Innovations

Technology continues advancing casting capabilities, opening new possibilities for design and production efficiency.

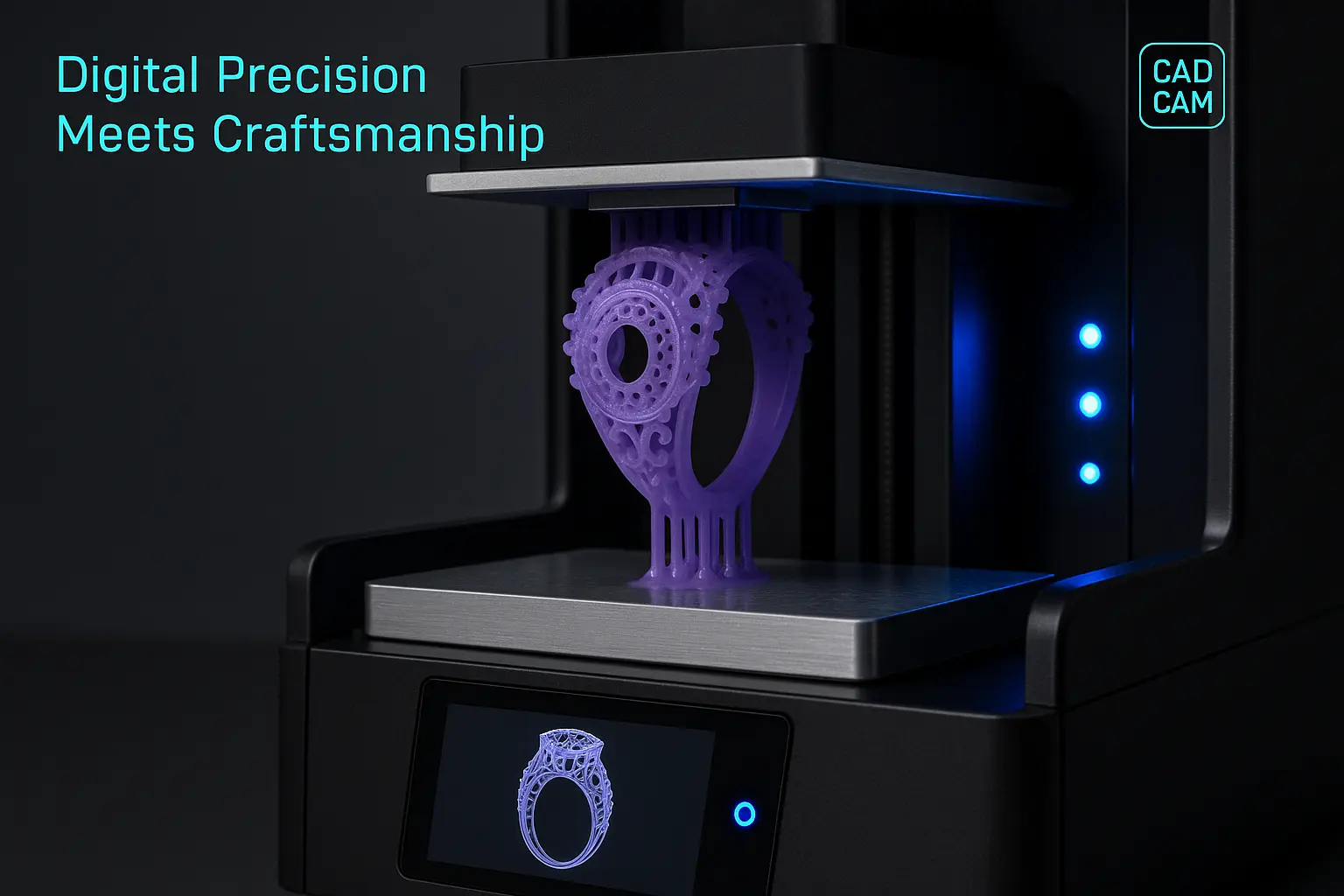

3D Printing Integration

Three-dimensional printing has revolutionized the model-making phase of lost-wax casting. Instead of hand-carving wax models, designers create digital files that 3D printers translate into physical resin models with extraordinary precision.

This technology enables design complexity that would be impractical or impossible with traditional wax carving. Intricate geometric patterns, precise stone settings, and innovative structural elements become achievable. Additionally, 3D printing allows rapid prototyping, letting designers refine concepts before committing to production.

CAD/CAM Technology Applications

Computer-Aided Design and Computer-Aided Manufacturing systems work together to streamline jewelry production while maintaining quality. Designers create detailed three-dimensional models on screen, adjusting proportions, testing design variations, and visualizing finished pieces before physical production begins.

These digital models provide exact specifications for manufacturing equipment, ensuring consistency across multiple pieces. The technology particularly benefits custom work, where clients can preview designs and request modifications before production starts.

Sustainable Casting Practices

Modern manufacturers increasingly adopt environmentally conscious practices. Improved melting equipment reduces energy consumption while maintaining temperature precision. Closed-loop systems recycle investment materials, and silver scrap gets refined and returned to production rather than going to waste.

Water-based investment materials have largely replaced solvent-based alternatives, reducing harmful emissions. These advances demonstrate that quality manufacturing and environmental responsibility can coexist effectively.

Minye Jewelry remains committed to sustainable manufacturing practices, continuously updating our processes to minimize environmental impact while maintaining the exceptional quality our customers expect.

Overcoming Common Casting Challenges

Even with advanced techniques, casting presents challenges that require knowledge and experience to overcome.

Shrinkage Compensation Strategies

Metal shrinkage during cooling affects all cast jewelry. Silver contracts approximately 1.5% to 2% as it solidifies, and manufacturers must account for this in mold design. Insufficient compensation results in pieces that don’t match specifications, particularly problematic for settings that must accommodate specific stone sizes.

Experienced craftspeople know that shrinkage rates vary based on casting temperature, cooling speed, and metal alloy composition. They adjust each mold design accordingly, ensuring final dimensions meet exact requirements.

Avoiding Common Casting Defects

Several defects can compromise cast jewelry. Rough surfaces, incomplete filling, or cold shuts (where metal fails to fuse properly) indicate process problems. Preventing these issues requires attention to multiple factors.

Investment material must have appropriate permeability to allow trapped air escape as molten metal fills the mold. Flask temperature must be high enough that incoming metal doesn’t solidify prematurely, yet not so high that it causes other problems. Metal temperature, pouring speed, and timing all contribute to successful casting.

Moissanite-Specific Precautions

While moissanite tolerates heat better than many gemstones, manufacturers still take precautions. Settings designed for moissanite account for the stone’s hardness and specific gravity, ensuring proper fit and security.

Prong thickness must provide adequate strength without appearing heavy or obscuring the stone. Bezel settings require precise dimensions to secure the stone while maximizing light entry. These considerations influence mold design from the earliest stages.

The Path Forward: Future Trends in Jewelry Casting

Casting technology continues evolving, promising even greater capabilities for creating exceptional silver moissanite jewelry.

Artificial intelligence and machine learning are beginning to optimize casting parameters, analyzing results to refine temperature profiles, timing, and other variables. These systems can detect subtle patterns that lead to improved consistency and reduced defect rates.

Additive manufacturing techniques may eventually allow direct metal printing, potentially bypassing traditional casting entirely for certain applications. However, traditional casting methods will likely remain relevant for many design types, valued for their proven reliability and cost-effectiveness.

Material science advances continue improving silver alloys, developing compositions with enhanced properties while maintaining the metal’s desirable characteristics. These innovations will enable new design possibilities and improved performance.

Creating Excellence: The Complete Picture

Superior silver moissanite jewelry results from combining advanced casting techniques with skilled craftsmanship and rigorous quality control. Every step matters, from initial design through final finishing, and manufacturers who master these processes create pieces that stand apart in quality, beauty, and durability.

Understanding these techniques helps you appreciate the value in well-crafted jewelry and make informed decisions when selecting pieces for your collection. Whether you seek classic elegance or contemporary innovation, the manufacturing methods behind each piece directly influence its quality and longevity.

At Minye Jewelry, we bring together cutting-edge casting technology, traditional craftsmanship, and unwavering commitment to quality. Our silver moissanite pieces reflect the careful attention and advanced techniques described throughout this article, resulting in jewelry that exceeds expectations and provides lasting satisfaction.

When you choose jewelry created with advanced casting techniques, you invest in pieces that combine beauty with durability, artistry with precision, and timeless appeal with modern innovation. The result is jewelry worthy of life’s most meaningful moments and treasured for generations to come.